FML Group have been assigned 10 percent of resource on quality assurance, in order to meet the company policy “to design and build quality”.

Our quality target 100% eligibility rate of products. 100% eligibility rate of process The process of quality control pervades all manufacturing stages from:

-BOM/AVL review

-Order processing and material handling

-Incoming material control

-Engineering changes

-Testing jigs development and building production fixtures

-Proactive design for manufacturing (DFM) services

-Assembly to QA and delivery.

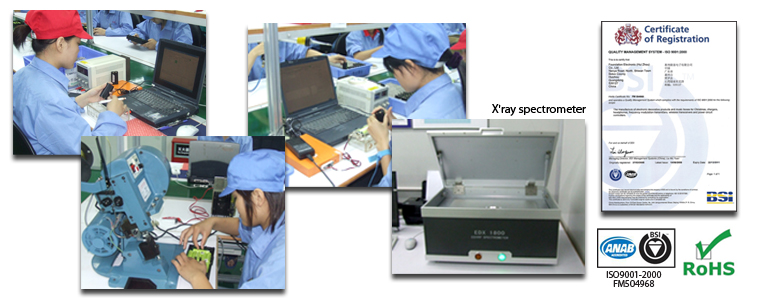

IPC certified personnel supervises and monitors the products being manufactured. Detailed instructions and specifications posted in production area are set to pre-assigned standards, which must be compiled as quality procedures. Implement SPC data to monitor any deviation and yield of the production. All finished products are subjected to vibration test, drop test, humidity test and burn-in test before delivery per the instruction from our customer.

Using sophisticated equipments including automatic inspection machine (AOI), in-circuit testers, BGA inspection station and optometer together with series of control points are operated by our QC and QA team to test electrical, mechanical and cosmetic performance. We are backed by our experienced engineers, technicians and production staff who are trained to perform QC inspections.

FML Group has been certified with ISO9001. Quality-oriented is our main goal and commitment to give our customer full satisfaction of our manufacturing services. Our quality and material control are exceptionally organized to produce high quality products. All control procedures are standardized and documented, audited by ISO9001 bodies to certify our standard. And since 2006 all our production processes and materials have been compliant with the RoHS directive.